Design in Autonomous Systems

Can We Understand Systems by Transforming Design?

By Pelin Celik and Jan Vietze, January 2019, Berlin

More and more products take over the autonomous communication from device to device for the optimization of actions and processes with the aim to create more security and reliability. Especially the development in the area of artificial intelligence (AI) will lead to significant changes in the area of future working and user experiences. If products no longer need the obvious interaction requirements with the user, this can open up new possibilities in product design or the transformation of design and focus more on haptic and emotional qualities. The user environment becomes a multi-sensory experience between authentic artifacts and artificial intelligence, away from unimaginative functional surfaces of selective interaction and towards emotional experiences that are shaped by the empathy of the designer. The increased use of robots in the area of service will bring new possibilities for process and interaction design with new types of machines. Ultimately, psychological aspects such as subjective perception and emotions in interaction will determine the success and acceptance of these new technologies. In times of rapid digital developments, the role of the designer will continue to become more diverse and complex in the future. These complex and contradictory design tasks already demand more than just finding the most suitable solution for a problem. Rather, they demand a critical, explorative and systemic discussion of the various issues. Design can shape human experiences and can initiate a dialogue on technical or socio-political questions in search of answers, if design is understood as a process of a holistic system and not only as its result.

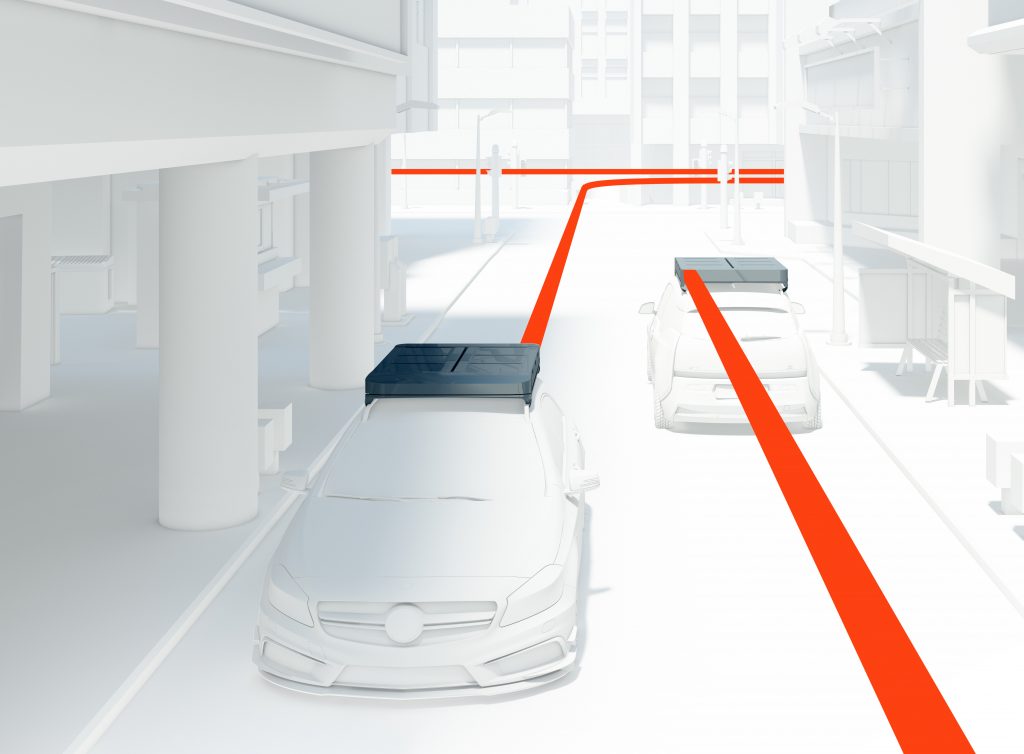

It is the year 2030 for us; in addition to highly automated vehicles, established car sharing companies offer highly automated mobility with a highly automated driving experience. What sounds like far-off dreams of the future is being pushed forward at full speed in the automotive industry. The vehicle of the next digital revolution will be autonomous, networked and electrically powered. In order to safely achieve this goal, the next step in the future will be highly automated driving as an intermediate step to autonomous driving. This will include in particular the consideration of new needs and experiences of the users, the so-called User Experience (UX), resulting from the new mobility and digitalization, especially in large cities. The consideration of UX questions familiar procedures and provides new ideas for innovative solutions – always based on the designer’s basic need to understand the user and his experience or the complexity of the entire system.

Highly automated vehicles will optimize and regulate the road traffic of the future by networking data and objects. It remains to be seen to what extent the user will be denied in his autonomy and competence in everyday life and, in particular, how this will be questioned by the designer. In the context of best practice projects in the study program of Industrial Design at the HTW Berlin in cooperation with Berlin based companies of the automotive industry, the importance of the so called “driving fun” for the user of highly automated vehicles or the feelings and processes that can occur when the vehicle control is temporarily handed over to a machine were investigated in the course of this study.

Best practice project UX MOBILITY 2030 – Artificial intelligence, gestures and peripheral perception in highly automated vehicles

AURIGA (lat. the wagon driver) is a cockpit system for highly automated vehicles. Auriga controls the vehicle, communicates with the user and uses its ability of peripheral perception. The road image with all important traffic participants is projected on the surface between dashboard and windshield. This area is perceived peripherally both while looking at the road and the dashboard. So you can work while driving, watch movies or surf the internet and still be able to take the wheel within 8 seconds if necessary. It is controlled with gestures that are derived from intuitive behavior. To move in a direction, you point in that direction, to accelerate you push your hands forward and to brake you clench your fist. In this way the autopilot can also be oversteered.

Equipping analog products and systems with additional sensors and electronics can enhance the performance of products in many areas or even make certain functionalities possible in the first place. Especially in the area of medical body-related tasks, future potentials become clear. Such assisting, intelligent systems can help to prevent dangerous situations or provide additional information in an emergency. Today, “autonomous” devices such as intelligent wearables are already making everyday life easier for users, and technologies such as virtual and augmented reality will change this situation even more. Here, too, holistic design concepts will be in demand that reflect new design visions on the basis of the expected technical development, which students of industrial design at the HTW Berlin pursue in an interdisciplinary and international way.

Best practice project of a football helmet

Even if the majority of injuries at football matches do not affect the head, head injuries can have very serious consequences, both short-term and long-term. Chronic traumatic encephalopathy is a degenerative disease of the brain and occurs mainly in athletes (boxing, American football, rugby, ice hockey). The innovative helmet protects the player better against direct force on the head. In addition, the construction of the helmet allows the outer shells to move partially independently, so that less rotating forces are transmitted to the head. The helmet measures the G-load via a chip in the neck and one in the mouthguard and sends them via Bluetooth to a Smart Device. The app provides information about the player’s tackling behavior. Coaches can thus identify players who use unfavorable tackling techniques and expose their heads to many collisions.

In order to meet the demands and challenges of our society, it is essential that the design of processes and services increasingly shift into the focus of industrial design. A bachelor thesis from the Industrial Design course at the HTW nBerlin deals with the additive manufacturing technology of selective laser melting (SLM) and the effects of this technology on the production landscape in cooperation with the Fraunhofer Institute for Production Systems and Design Technology, Berlin.

Best practice project of a bicycle frame

The example of a bicycle frame shows how this manufacturing technique merges the fields of design, mechanical engineering and production and enables a completely new form of individual mass production. The process of creating a bicycle frame – adapted to the needs and wishes of an end user – from the aluminium design, construction and manufacturing process through the SLM process to the final assembly will be shown. The aim is to show how integrated digital production leads to a paradigm shift in the development process. Thus, the new design possibilities of parametric and algorithmic design, for example topology optimization, can be easily converted into real products thanks to additive manufacturing. This leads to a greater variety of future products, which, due to the new freedom of design, also enable extensive functional improvements, such as individual ergonomic adaptations. ■